|

| S197 Quiet Watts Linkage |

Watt's linkage (also known as "parallel linkage") is a type of mechanical linkage invented by James Watt (19 January 1736 – 25 August 1819) in which the central moving point of the linkage is constrained to travel to a straight line within a certain travel length. Its applications in automobile suspensions are that of allowing the axle of a vehicle to travel vertically while preventing sideways motion. This type of locating device, however, does so much more than that for a race or track prepared vehicle.

|

| SN 97 Watts Linkage installed |

Watt's linkage is used in the rear axle of some car suspensions as an improvement over the Panhard bar or rod, which was designed in the early twentieth century by a French car company of the same name. Both methods intend to prevent relative sideways motion between the axle and body of the car. Watt’s linkage approximates axle movement in a vertical straight line motion more closely, and does so while locating at the center of the axle rather than toward one side of the vehicle, as more commonly used when fitting a long Panhard rod. By locating the center of the axle the roll center of the vehicle can be clearly defined and thus be predictable and, in the case with Griggs Racing Watts links, completely tuneable. In fact we have found that our tuneable watts linkage lends itself to consistently Quicker lap times than a Panhard Bar. The reason for this is because, unlike a Panhard Bar, both right and left cornering characteristics are identical. This is due to the fixed roll center relative to ground of the GR40 Watts link, which is not so with Watts links from other companies.

Not only are the linkages fully adjustable laterally for accurate real axle alignment, but also the Pivot which locates the roll center is vertically adjustable allowing quick easy and tuning of chassis balance with accurate and predictable results simply by unbolting it and moving it up for reducing understeer, and down for reducing oversteer. This Increases controllability and driver confidence under power and in cornering because the driver can predict easily what the vehicle will do. By having this adjustable rear roll center drivers have found maximum corner exit traction achievable while optimizing corner balance for faster lat times, and therefore optimizing their driving experience.

|

| SN 95 Watts Linkage/ TorqueArm assembly |

When used with a TorqueArm lateral tire loads are made independent of changes in engine & brake torque loads, vastly improving handling and power, applied performance, and braking making this rear suspension geometry THE best choice for competition vehicles, drag, autocross, road racing, and serious open tracking. However if a TorqueArm cannot be used due to race class rules or various other reasons the Griggs racing watts link can be installed independently of our TorqueArm on any 9 " rear axle in any vehicle. On Cars equipped with 8.8 rear ends, the addition of a TorqueArm Delete Bracket is required.

|

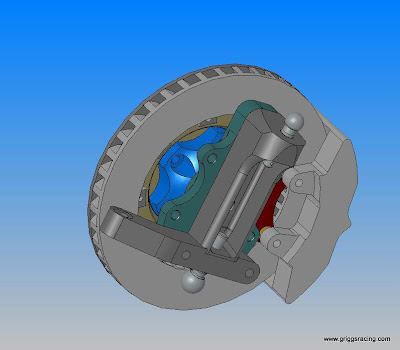

| Watts Linkage for Ford 8.8" with TorqueArm Delete |

You can also trust that the Griggs Racing Watts link kit is going to be light adding minimal sprung and unsprung weight when compared to all other lateral linkages on the market. Not just light but also very strong; No bends in the main brackets affords zero flex and zero chance for failure of a well set up system. large tire guys need not fear either since the Griggs racing Watts linkage kit positively locates the rear axle laterally use of maximum tire sizes is allowed with the least chance of rub.

A further feature is the progressive failure design. This feature has been proven real world testing. Lateral impact, such as impacting a curbing, can result in serious damage in competitor's systems, but in the GR40 Watts link each part is designed to fail in progression. If the standard Watts link with Aluminum Arms is installed, in an impact, the arms bend first, then the bell crank fails, then the main plate. This usually saves the Aluminum rear end cover and the chassis bracket, so a quick repair can often be made so the car can continue to race. This is not possible with copy cat designs that delete the Main plate.

Therefore the very best choice in a lateral axle locator available regardless of ride height movement is The GR40 Watts Link.

Want one for your ride? Contact us at Sales@Griggsracing.com to get yours.

Want one for your ride? Contact us at Sales@Griggsracing.com to get yours.