- Increases rear traction (forward bite)

- Decreases stopping distance significantly

- Engineered to maximize ground clearance

- Can be used without other rear suspension modifications

- Presets pinion angle

- Longer U-joint life

- The most driver friendly way to hook up power.

- Allows for the removal of the rear upper control arms and quad-shocks on cars so equipped.

- Decreases snap-oversteer

- Corrects rear roll center location

- Decreases rear bind

- Inspires driver confidence

The TorqueArm when coupled with a Panhard bar or Watts link is the best in terms consistency of control and improved braking due to is constant and consistent tire loading regardless of ride height changes as the car encounters surface irregularities, cresting hills, etc. Compared to 3 link, 4 link, 5 link or IRS designs, the improvement in car control under power offsets any arguable merits of the other systems in a high powered rear drive vehicle that is without aid of high down-force aerodynamic devices. For this reason the same basic geometry is used on most Sprint Cars, Supermodifieds, Late Model Stock Cars, and other professional race cars around the world where rules allow.

TorqueArm geometry would be used in more forms of road racing were it not for rules restrictions in various organizations such as TransAm, and NASCAR, or where aerodynamic packaging is the priority of design as in Indy cars and Formula 1.

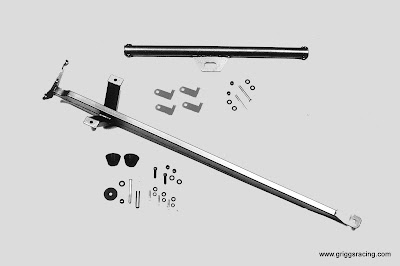

Griggs Racing was the innovator of TorqueArm design application to the Mustang in 1979, and has produced many versions and improvements since its inception. Currently there is one basic off the shelf versions of Griggs Racing TorqueArms; Severe Duty. The severe Duty TorqueArm is intended for most applications; from street use on cars with stock engines and transmissions to cars with over 500 RWHP and sticky tires that are drag raced, brutally road raced, autocrossed, or similarly abused. The structure of the severe duty TorqueArm consists of the appropriate appendages for the model and axle used, attached securely to the severe Duty arm.

These are not hard and fast rules and when in doubt you should contact us for specific recommendations for your application. The Severe Duty TorqueArm is the most popular and Bruce Griggs races his AIX cars on the severe Duty TorqueArm and his cars exceed the power level described above and still win while being completely durable race after race. If absolute durability regardless of abuse is the priority, you should choose the Severe Duty unit which is the most popular or contact engineering@griggsracing.com for a specific recommendation for your application.